News

November 18, 2022

Most wanted: Our Hybrid plate heat exchanger

At the end of the year we are delighted about the high demand we have received for our fully welded hybrid tubular and standard plate heat exchangers. On behalf of a wide variety of companies, we (did) manufacture a vacuum condenser, a heating condenser, two preheaters and steam converters each, several plate packages for a retrofit of an existing plant, and received a follow-up order for four of our latest fully welded plate heat exchangers - the VAU COMPEX. This variety shows once again how versatile our fully welded hybrid tubular and standard plate heat exchangers are.

Read more now…

January 21, 2022

New cooperation partner for Benelux

We are proud to announce L. TAS & Co. BV as excellent partner for Benelux to expand our international sales network. The company was founded in 1938 and specializes in advising and selling products from the mechanical engineering, (petro)chemical, food, HVAC and hydraulic industries. From now on, L. TAS & Co. will sell our brazed and fully welded hybrid tubular plate heat exchangers in the Benelux region and act as a regional contact. We look forward to a long-term and successful partnership.

September 6th, 2021

VAU shipped Vaccum condenser for Asia

The vessel is based on the advanced Hybrid Tubular Plate Heat Exchanger and is specially designed for the condensation of steam under vacuum. It is approx. 2.9 m high, approx.2.35 m wide, has a depth of 1.35 m and an empty weight of about 5,150 kg. On a heating surface of 263 m², it offers a heating output of 2.5 MW. Steam on the primary side and water on the secondary side are guided in cross flow.

July 13th, 2021

New heat condensers for municipal utilities

After a construction period of three months, two new heat condensers have been shipped to a power plant in Augsburg (Bavaria). Each apparatus weighs 4.6 tons, has a heating area of 203 sqm and 24,000 kW power. As a heating element a fully welded hybrid tubular plate heat exchanger is used. Steam at a temperature of 160 °C is fed to the primary side, where it cools down to around 90 °C. Water is guided through the secondary side via cross-flow process and heats from 65 to 130 °C.

May 11th, 2021

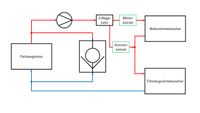

Combined heat and power in caravans - VAU supplies the right components

Matthias Meier, Commercial Director of Fahrzeugbau Meier GmbH, explains how warmth is implemented in an environmentally friendly way for the living room on wheels. The company is a leader in accessories for CVs and commercial vehicles. VAU Thermotech has been supplying the company with heat exchangers regularly since 2014. Almost 3,000 units have now been installed in the vehicles.

April 27th, 2021

VAU shipped a 13 tons heating condenser to Hamburg

It took about half a year to complete the heating condenser for a power plant in Hamburg. But now the device has been lifted onto the low-loader in our plant in Heldrungen and sent on its way. The heat exchanger has a weight of 13.1 tons; is 4 meters high, 2.5 wide and 3.2 meters long. At its destination the condenser is used to prepare hot water for district heating. The apparatus has a heating surface of 565 m² and a capacity of 65.2 MW. The core of the device is a hybrid tubular plate package.

April 22nd, 2021

VAU Thermotech is investing six-figure amount in the expansion of quality assurance

With the new pressure and leak test facility for our brazed plate heat exchangers, we are increasing production efficiency, at the same time increasing quality assurance and making it easier for our customers and ourselves to trace our products. The new device has two test chambers operated alternately. While the analysis of one device is still in progress, the second can be removed immediately after the test and replaced with a device that is still to be tested. In this way it is possible to roughly quadruple the test cycle.

September 2020

Hybrid Heat Exchanger grants CO2 reduction

Four fully welded Hybrid heat exchangers for a fermentation residue evaporation plant of an East German manufacturer of biofuels were certified by TÜV Süd inspectors. Our plate heat exchangers are compliant with the Pressure Equipment Directive (PED - 2014/68/EU). Usually, fermentation residues still contain a high amount of water which will be squeezed by our fully welded Hybrid heat exchangers. With the support of our heat exchangers these fermentation residues are made usable for a further processing stage. The result: additional CO2 reduction and a better energy balance. A special feature of this construction are the removable covers for cleaning purposes.

August 2020

VAU gets the steam up!

Delivery and installation of worldwide unique six-stage hybrid plate heat exchanger completed in record time. After just 13 months production time, it’s done: Six hybrid plate heat exchangers with a total of more than 6,000 square meters of heating surface at a weight of 19 tons each were delivered with additional containers in full and on time to BENEO. Thanks to the precise and complete planning by VAU Thermotech, all equipment and containers were installed within a few hours after they had been delivered to the customer.

April 2020

New innovation hotspot in Munich

After we relocated our factory from Munich to Thuringia in January 2015 we only had a small office in Munich. With now almost 240 square meter office we shine in Munich in new splendor! The office is located near the Munich trade fair in Riem and is optimally connected in terms of transport. "In order to create closer customer proximity in southern Germany and South-Europe we decided to open a new office with new modern business and conference rooms. For our existing and prospective customers in southern Germany travel times for training or product presentations are shortened, ”says the CEO, Osama Nasser. The new office should serve as an innovation hotspot for the development of new products.

.jpg/picture-200?_=17ace690d08)

.jpg/picture-200?_=17ace690920)

_1.jpg/picture-200?_=175f531dc58)

.jpg/picture-200?_=1747368ad10)