Hybrid Tubular Plate Heat Exchanger as Heat Condenser

Intelligent alternative to Shell & Tube Heat Exchanger

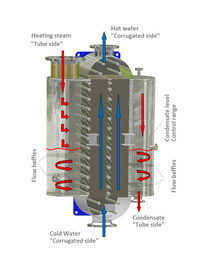

Functionality of VAU Hybrid Heat Condenser

The hot water preparation in a hybrid tubular plate heat exchanger is done in cross flow: steam enters into inlet headers from the top, flows horizontally through the tube side and condenses. Water which is pumped over the corrugated side is heated. The condensate on the tube side accumulates at the vessels bottom collects on the pipe side on the underside of the container and is forcibly guided via baffle plates to the condensate outlet nozzle in several ways. This means that it is precisely super-cooled to nominal temperature.

By the special condensate stop control of VAU Hybrid Tubular heat exchanger it is possible to adjust the heating capacity almost continuously between 0 and 100%. The prompt control capability come along with optimum heat transfer and high heat surface density opposite to a Shell & Tube Heat exchanger.

Shell & Tube Heat Exchanger vs. Hybrid Tubular Plate Heat Exchanger

Shell & Tube | Hybrid Tubular | Advantages of Hybrid Tubular Heat Exchanger | ||

capacity | MW | 51 | 52 | 1,9% more capacity |

surface | m² | 800 | 382 | approx. half heating surface for the same capacity |

weight | t | 26 | 7,8 | weight saving up to 75% |

length | m | 10 | 2,3 | approx. 1/5 of set up area |

width | m | 1,3 | ||

height | m | 3,6 | ||

diameter | m | 1,6 | ||

set up area | m² | 16 | 2,9 | |

set up space | m³ | 25,6 | 10,7 | more than 50% space savings |

set up | - | horizontal | vertical | more compact power house |

By the more compact design of the Hybrid Tubular Plate Heat Exchanger a higher capacity can be realized compared to the Shell & Tube. Material, weight as well as manufacturing costs are reduced remarkable.

Hybrid tubular plate heat exchangers are economic, flexible in design, have low weight and offer high heating capacity at less space.

Please contact us for your inquiry

Manfred Hermanns, Dipl.-Ing.

CTO / Technischer Leiter

Phone: +49 2161 30 370 16

E-Mail: manfred.hermanns@vau-thermotech.de

Frank Betzold, Dipl.-Ing.

Project Engineer

Phone: +49 34673 1683 23

E-Mail: frank.betzold@vau-thermotech.de